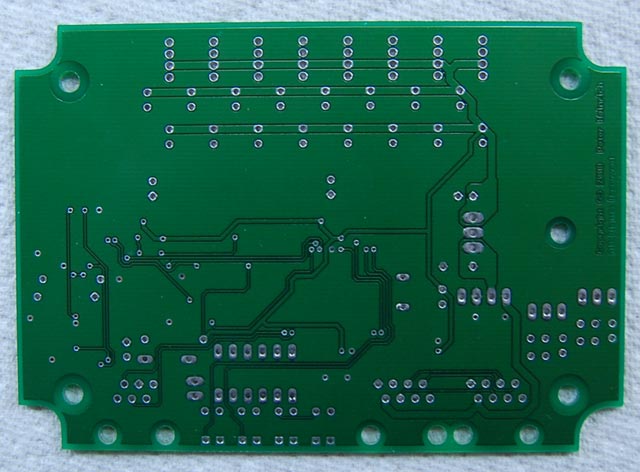

First PCBs

Just received the first printed circuit boards for my Ifos project.

I used OurPCB, which was inexpensive and fast. Board quality is great—but then I have zero experience evaluating PCB manufacturers. Total cost was $98 for 10 boards (4.15” × 2.9” × 2 layer, 2-sided mask, 1-sided silk), including a one-time $50 tooling fee and $30 shipping. Electrical testing was free, with lead time right around 10 days.

Choosing an off-shore manufacturer (OurPCB is in China) was a difficult decision. There are many domestic companies I could have used, but all were 5 to 25(!) times more expensive. BatchPCB is a little more competitive, at just above 3 times the cost, but only because they outsource their manufacturing overseas themselves. They are associated with SparkFun, however, which is almost reason enough to use them.

In the end, though, I don’t really know what that extra money buys. Better working conditions? Higher pay? More stringent environmental controls? Improved quality?

Unfortunately, in the rush of last-minute changes before sending the gerbers off to manufacturing, I moved a component and caused it to overlap a trace for a different signal. A design rules check (DRC) caught the problem, but not until I remembered to run it—the next day. Oops.

Within hours of receiving the boards, though, I discovered an even bigger issue: the land pattern I created for the MAX6957 LED driver was based on the 36-pin SSOP, which uses 0.8mm pitch. I designed the board with the 28-pin version in mind, but since I had a couple samples of the larger chip, I used them as a model. Unfortunately, the smaller version uses 0.65mm pitch. Oops.

The moral of the story: don’t assume you know it all, don’t forget that last DRC, and always check the datasheet! Version two should arrive around July 18. This time I chose blue solder mask, just for the fun of it.